rockwell hardness test scale chart|rockwell c hardness chart : trader The Rockwell scale is a hardness scale based on indentation . web4 de ago. de 2020 · Conecte SUS Cidadão permite acessar resultado de exames de Covid-19. Publicado em 04/08/2020 19h49 Atualizado em 01/11/2022 11h23. Por meio do portal .

{plog:ftitle_list}

webpretinha do rabao (17,965 results) Report. Sort by : Relevance. Date. Duration. Video quality. Viewed videos. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Next. 360p. Pretinha novinha .

rockwell steel hardness chart

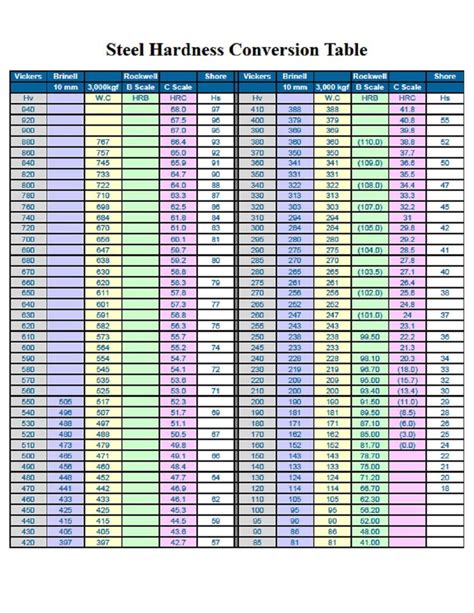

ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Brinell and Rockwell Hardness Conversion Chart - These Conversion Tables .

The Rockwell scale is a hardness scale based on indentation .

2000kn universal testing machine

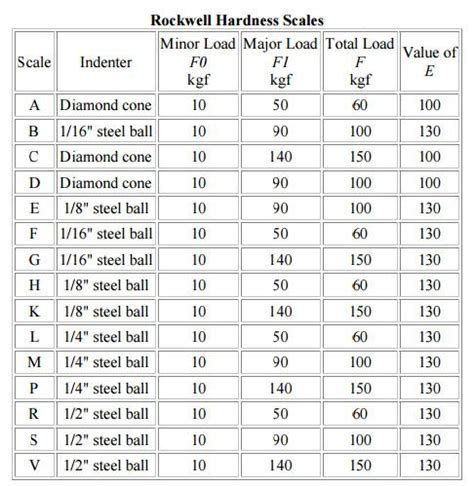

The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell .1. Obtain the Vickers Hardness Value (HV): Conduct a Vickers hardness test on the material using the appropriate indenter and load for your material. 2. Consult a Conversion Chart: Use .Here are the hardness tables and conversion charts for you. Table of Contents. I. Scale – Symbol – Indenter and Load Force. II. Rockwell C Hardness Range. Hardness Conversion Chart for Non-Austenitic Steels (Rockwell C Hardness . Rockwell hardness is expressed in three scales: HRA: Uses a 60kg load and a diamond cone indenter, suitable for extremely hard materials like hard alloys. HRB: Uses a 100kg load and a 1.58mm diameter hardened steel .

There are several different Rockwell Scales denoted by various letters requiring different loads or indenters during hardness testing. The Rockwell hardness scale chart for regular Rockwell scales and superficial Rockwell scales are . This table shows approximate hardness of steel using Brinell, Rockwell B and C and Vickers scales. These conversion charts are provided for guidance only as each scales uses .

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.

2. Rockwell Hardness Test. The Rockwell test measures hardness by assessing the depth of indentation created by an indenter (either a diamond cone or a steel ball) under a specific load. It is widely used in manufacturing due to its speed and efficiency, with different scales (e.g., Rockwell B, Rockwell C) for various materials.Rockwell C scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with . depth and hardness are known. Minimum thickness charts and the 10:1 ratio serve only as guides. After determining the Rockwell scale based on minimum thickness values, an actual test should be made . The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal .You can choose a Rockwell hardness scale with suitable test forces (load) and indenter size according to the material thickness that must be used in the procedure. . VI. Rockwell Hardness Scale Chart Hardness Conversion for Rockwell B scale: B. A. E. 15T. 30T. 45T. HV. HK. HB. HB. 30 kgf. 60 kgf. 100 kgf. 15 kgf. 30 kgf. 45 kgf. Vickers .

Brinell [HB] is one of the most common units used for listing the hardness of steel materials. The test is done with a 10 mm steel ball pressed with 3000 Kgf (6,614 Lbf). Common values for machined materials range from 100 HB for very soft materials up to 650 HB for heat-treated steels.. The advantage of Brinell [HB] over Rockwell [HRC/HRB], is that the whole range is .Rockwell: Rockwell Superficial: Brinell: Vickers. Shore : A: B: C: D: E: F: 15-N: 30-N: 45-N: 30-T: 3000 kg: 500 kg: 136 . Approx Tensile Strength (psi) 60kg Brale .

indenters; however, all of the ball scale Rockwell hardness tests (HRB, HR30T, etc.) and most of the Brinell hardness tests preformed to develop . for the errors in using a conversion chart. Even in the case of a table established for a single material, such as the table for . sured hardness and test scale shall be indicated in parentheses .

Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is .

Definition of the Rockwell hardness test method The Rockwell hardness test methods are described by a number of scales, characterized by a standard, an indenter type, and a load. Examples of Rockwell hardness test methods: HRE 1/8” diameter tungsten carbide ball indenter, 100 kgf major loadHardness scales Hardness according to Rockwell (HRc - cone and HRb - ball) The depth of penetration of an indenter is measured by loading a certain force. Either a ball (HRb) or cone (HRc) can be used. It is a quick and simple measurement, especially suitable for cutlery steels. Vickers hardness test (HV) A pyramidal diamond indenter with a 136 .A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select the most suitable scale between Rockwell B (HRB) and Rockwell C (HRC). This article compares two types of Rockwell hardness to help you find the most ideal of the two for your hardness testing and conversion needs.

Principle of Rockwell hardness scale The Rockwell scale determines the hardness by measuring the depth of penetration of an indenter. This happens under a large load compared to the indentation made by a pre-load. Different scales use varied loads or indenters such as: . The Rockwell M hardness test is not valid for plastics that are less .Here we compare the Vickers hardness method with the Rockwell method and their conversion charts. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are; . Rockwell Hardness Test (HRC) C scale (HRA) A. 60kgf diamond conical indenter . Rockwell Hardness test is the most widely used method but in some cases Vickers .Hardness Conversion Table – Brinell, Rockwell,Vickers – Various steels . (archived November 11, 2011) Rockwell to Brinell conversion chart (Brinell, Rockwell A,B,C) Struers hardness conversion table (Vickers, Brinell, Rockwell B,C,D)

Rockwell hardness testing of plastics is described, and conversion charts correlating various scales are presented. The Rockwell E, M, and R scales of hardness are commonly used for 'hard' polymers such as nylon, polystyrene, acetal, and polycarbonate. . The hardness testing of plastics is most often measured by the Rockwell hardness test or .Conversion table/chart for Brinnel and Rockwell hardness scales and tensile strengths. Buy metals and plastics online in small quantities, cut to order. . The table below converts Brinell Hardness to Rockwell Hardness scales and vice versa, then compares those to the approximate tensile strength that those scales indicate. . FREE Mill Test .

Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool for Rockwell Hardness Test. The Rockwell hardness test measures hardness by determining the net increase in depth of an impression as a load is applied. It uses a minor load to seat the indenter and then a major load to create the indentation. The difference in depth between the minor and major loads provides the Rockwell hardness number.

Worldwide service network | 1-800-473-7838 service@buehle r.com Providing service and support that is dedicated to ensuring the highest quality This is where the Rockwell Hardness Scale comes in – and we’re going to spend some time exploring this topic so the next time you come across a knife brand claiming to have the “sharpest”, “hardest” or even the “toughest” knife, you’ll know the truth. . The test is performed more than once to determine an average rating and .

Superficial Scales. The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are useful when a sample may be too brittle or thin for a standard Rockwell hardness test. Superficial Rockwell hardness tester: 15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y Polymer/Plastic .

Hardness Conversion Chart with standards including Brinell, Rockwell B scale, Rockwell C scale, Vickers and others. Skip to content. Search for: SEARCH. 1-888-934-7463 [email protected] ISO 9001:2015. Oxmoor Plant: 2101 Wenonah-Oxmoor Road . Knoop Hardness Rockwell A Scale Rockwell F ScaleHow To Operate The Analog Rockwell Hardness Tester ; Cylindrical Correction Chart; Hardness Conversion Chart - Rockwell "B" Hardness Range; Hardness Conversion Chart - Rockwell "C" Hardness Range; Hardness vs Minimum Thickness Chart; Rockwell Scale-Indenter-Load Chart; Contact Us. About Us; Store Policies; Blog The Rockwell C Scale measures the hardness of blade steels. Ratings are called “C Ratings,” or they’re abbreviated “HRC,” or “RC.” . Reference our chart below to compare the typical hardness ratings for the most popular blade steels on the market today. How is a Blade Hardened? Once the rough shape of a blade is hammered out, it .

universal testing machine 2000kn

Resultado da 19 de jan. de 2021 · »INFORMAÇÕES« Titulo Traduzido: Outlander: Guerreiro vs Predador Título Original: Outlander IMDB: 6,3/10 .

rockwell hardness test scale chart|rockwell c hardness chart